- Product Details

- Video Center

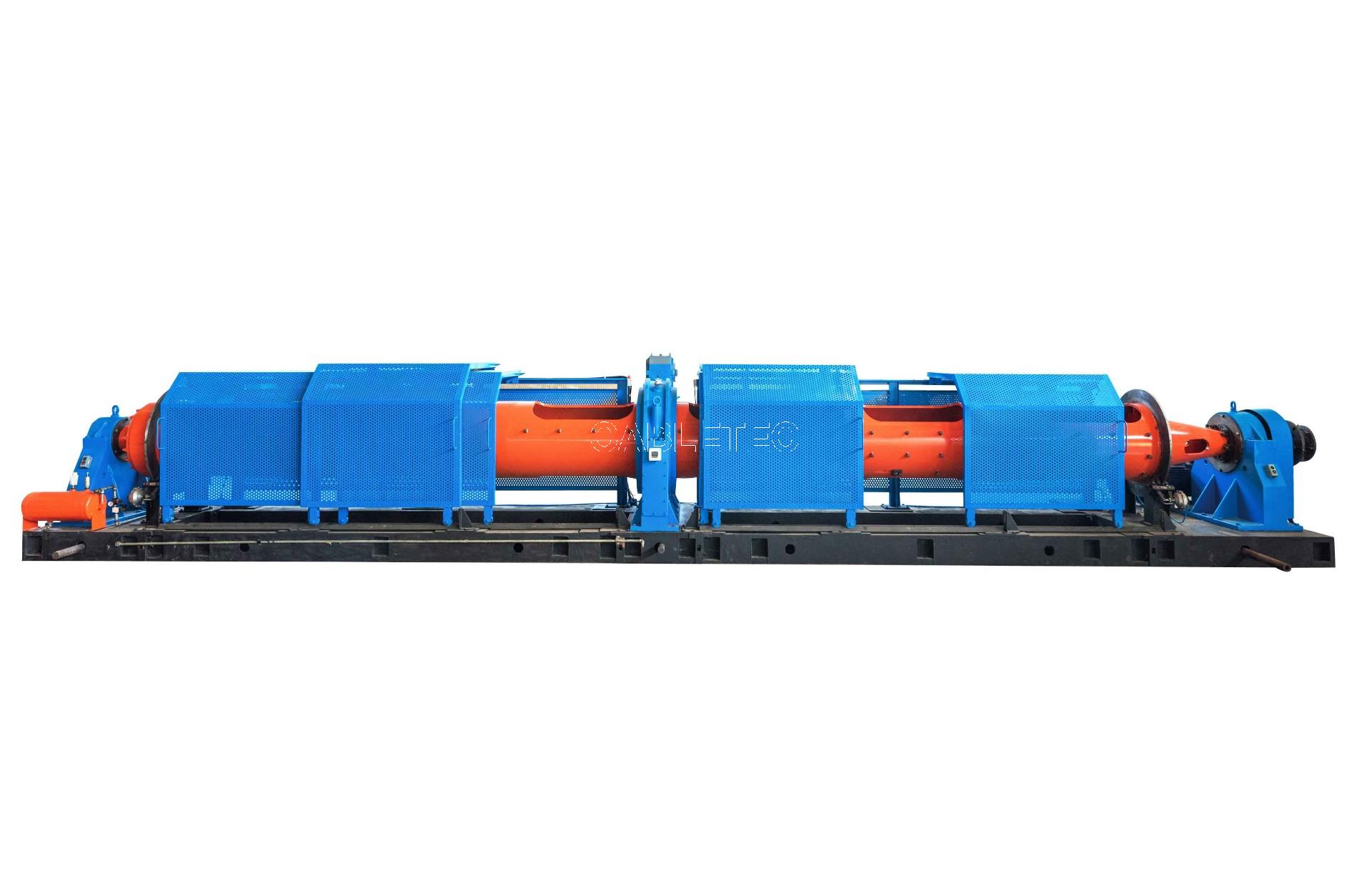

12/238 Optic-fiber secondary coating line

Application:

The optic-fiber secondary coating line is mainly used for extruding 2 to 12 core fiber outer diameter Ф1.5 to Ф3.0 mm fiber loose tube bundle tube and cable filling rope extrusion. Extrusion materials should be suitable for PBT, PP, PC and PE. The extrusion shape is round, uniform and smooth.

Equipment feature

2.1. The design speed of the production line is 800 M/Min, and the production speed is ≥500~600 m/min (Ф1.80 mm, thickness 0.30 mm, PBT beam tube)

2.2. Machine residual length control range: 0 ~ 3 ‰.

2.3. In order to improve the stability and reliability of the product, the cold water circulation system of the machine adopts automatic constant temperature control and is equipped with a refrigeration device.

2.4. The fiber filling system has a constant temperature control device to make the filling amount accurate, stable and reliable.

2.5. The key electronic control components in production are all made of high quality products with reliable quality and convenient maintenance.

2.6. The extruder adopts 60 type, and the screw ratio is 25:1.

Technical configuration:

Pay off bobbins | 12 |

Payoff tension | 0.4~1.5 N±0.05 N |

Payoff bobbin size | 25 km and 50 km two kinds of fiber optic discs |

Casing diameter | Φ1.5 mm~Φ3.0 mm |

Continuous production length | Max 50 KM |

Hot water tank water temperature | ~80 °C |

Refrigerator outlet water temperature | 15 ° C ~ 25 ° C (adjustable) |

Wire diameter deviation | ±0.03 |

Length control range | 0~3 ‰ |

Length control accuracy | ± 0.2 ‰ |

Length metering charge difference | ≤0.2 % |

Additional loss at room temperature | after plastic forming ≤0.02dB/km (average value is 0.01 dB/km) |

Machine power | ≈60KW |

Production direction | Contractual agreement |

Production line color | User specified |