- Product Details

- Video Center

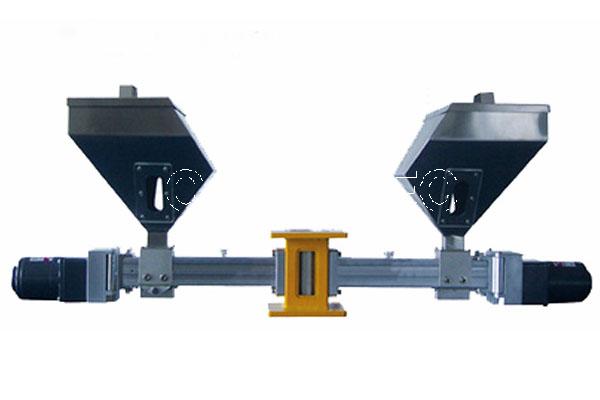

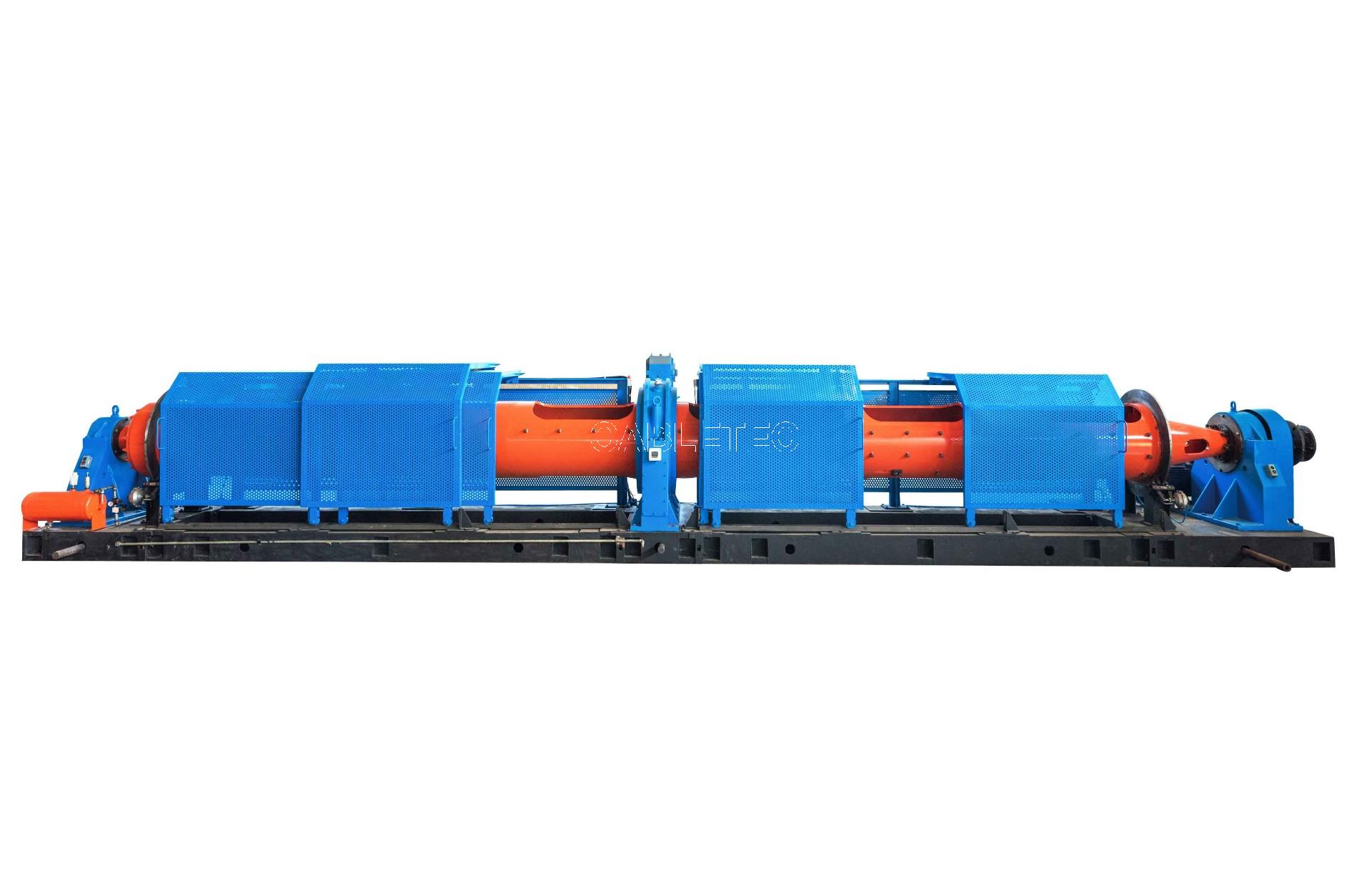

Cold feed vacuum rubber extruder for car seal and door seal

Application:

Cold feed venting rubber extruder is used for the production of the sealing strip in the car and door seal, window seal, and it can usmore than 40% PVC and add NBR materail. Cold feed venting rubber extruder can supply a range of low (<24%), middle (25%-30%), middle-high (31%-35%) and high (36%-42%) acrylonitrile content.

Specification:

Type | Ф75/20D | Ф90/20D |

Exhaust type | German Vacuum air pump, vents (with vacuum blockage) |

Regulatory loop | Adjusting ranges (0~45mm) to ensure different products from leaking from the venting hole |

Max extrusion pressure | 35MPa |

Central height | 1100mm |

Power supply | 3 phase 5 line 380V 50HZ |

Water supply source | Water temperature≤30℃, 0.2Mpa≤water pressure≤0.4Mpa (PH=6~8 Water does not contain a large amount of calcium, silica, salt, iron, etc.) |

Screw diameter | Φ75 C9(-0.17~-0.257) | Φ90 C9(-0.17~-0.257) |

Screw L/D | 20:1 |

Screw material | Japan SM645 | Japan SM645 |

Nitriding treatment | (δ=0.4~0.7) | (δ=0.4~0.7) |

Hardness | HV800~900 | HV800~900 |

Max RPM | 60rpm MAX | 60rpm MAX |

Water circulation | The central part of the screw has a circulating channel and a rotary joint. |

Extrusion section | CYC1 spiral water circulating |

Plasticized exhaust section | CYC2 spiral water circulating |

Feeding section | CYC3 water circulating |

Water pressure test of cooling system | 20(MPa)X1H |

Inner wall material | 38CrMoAL |

Nitriding treatment | δ=0.4~0.7 |

Lining | Centrifugal casting of the inner wall of the lining of the extrusion section |