1250D Main parameter

-Wire diameter of wire inlet: Φ1.0mm-3.0mm /7cores(copper wire )

Φ2.0mm-Φ6.5mm/2-4cores(PVC wire)

-Conductor section area of stranding: 3.5-50mm2

-Lay range(copper and aluminum): 40-350mm. Thumb wheel type setting automatic calculation and adjustment.

-Wire diameter of stranding:

-Copper wire: Φ3.0mm-7.9mm

-PVC wire diameter:Φ5.0mm-9mm.

-Stranding section (flexible strands):3.5-70mm2, strands of copper wire inlet: Φ1.0mm-4.5mm

-Stranding section (1 + 6): 3.5-50mm2

-Compacted copper:3.5-50mm2

-Compacted aluminum:3.5-70mm2

-Maximum line speed:150m/min

-Direction of twisting: S.Z. (Left and right twisting direction can be selected).

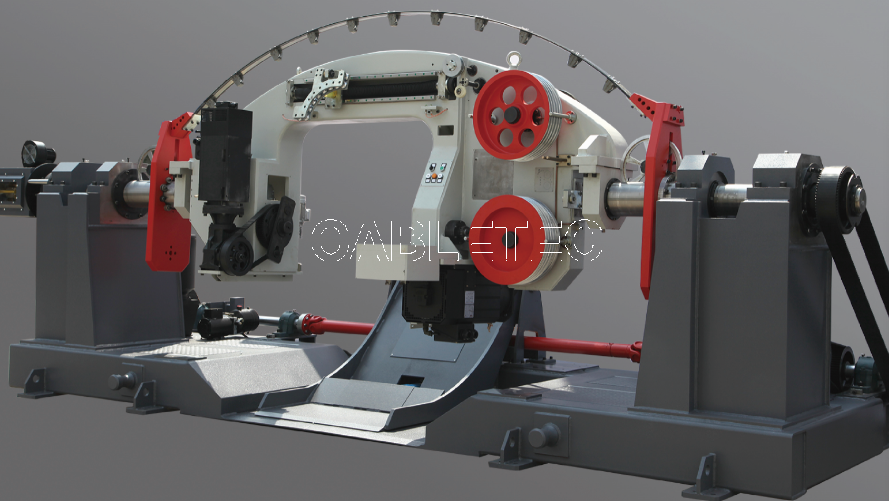

-Speed of rotation body: 800 RPM/MAX. (1600 Twist), normal working speed:500RPM

-Power:

Main frame: 55KW AC Motor + inverter control

Capstan: 30KW AC Motor + inverter control

Spool tension: 7.5KW AC Motor + inverter control

Traverse unit: 0.75KW induction motor + inverter control

Rotation die stand: 0.75KW induction motor + inverter control

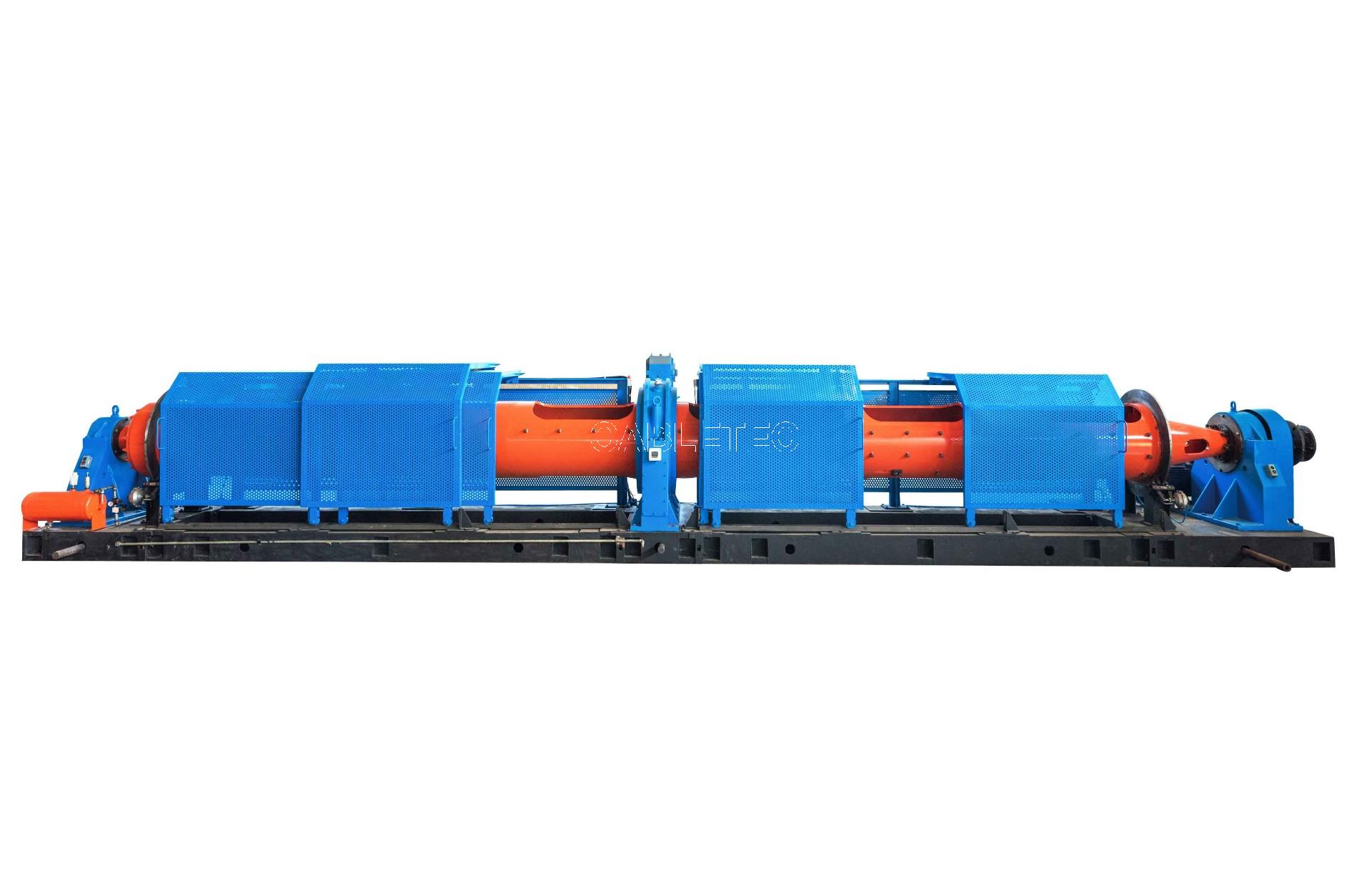

-Spool drum size: Max 1250mm

Spool load capacity: Max 5000KG

-Power source: 380V, 50Hz(or depend on customer’s requirement)

-Drum loading and unloading :

Type: Motor shaftless type.

Bobbin load /unload:by electric hydraulic lifting platform control

-Low noise design: Main machine noise is insulated by safety cover, noise below -80db.

-Brake: Adopt pneumatic brake.

-Control: PLC system control.

-Siemens Inverter control.

-Wire-broken stop indicate, and own pneumatic clamping device.It avoids to break wire during producing wire or threading wire on machines.

-Meter reached will be stop.

-Safety limit control.

-Lighting control inside machine.

-Used air pressure: 6Kg/cm2.

-Add a side door at back of safety cover to convenient maintenance.

-Add pressure wheel at the meter counting wheel.

-Carbon brush connection to use the cable.

Equipment content

-Wire inlet

-Base of the inlet wire

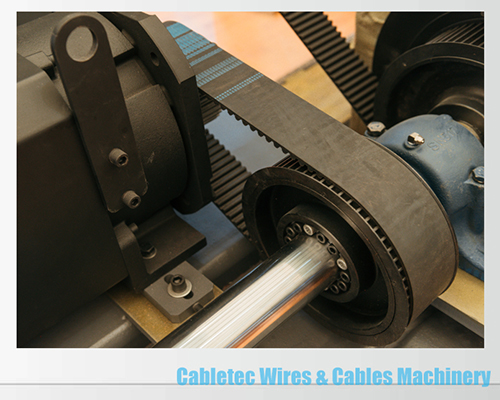

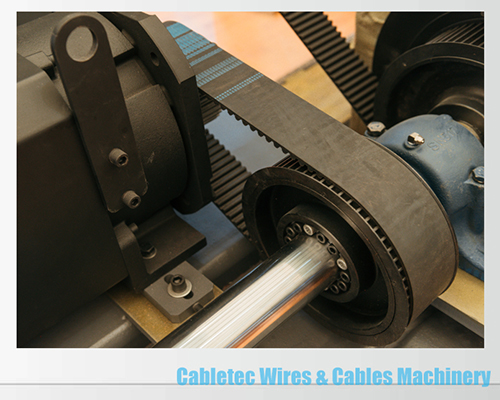

-Synchronous transmission system

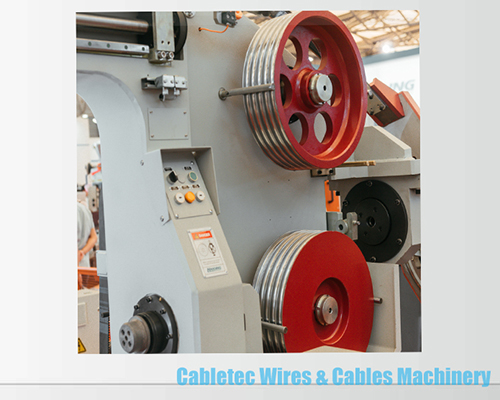

-Power

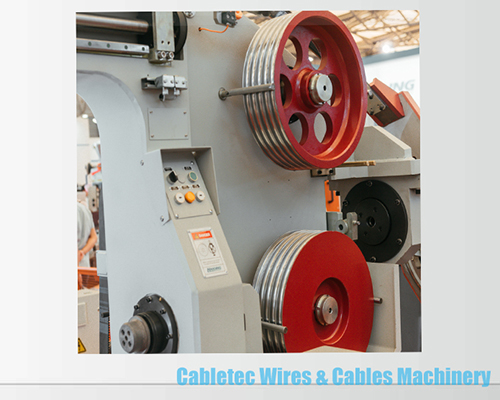

-Part of rotation body

-Bow part

-Cradle part

-Wire though die

-Traverse part

-Capstan part

-Adjustment part of spooling tension

-Suitable spooling tension adjustment part

-Bobbin load/unload part

-Stranding pitch setting part

-Electric control part

-Safety cover part

-Lubrication method

-Brake part

-Spare part

-Compression device

Download

Download