Monitoring cable producing line(Coaxial Cable)

| No. | Name and specification | Brand | Qty |

| 1 | 400mm Bunching machine | Cabletec | 1 |

| 2 | 500mm Bunching machine | Cabletec | 1 |

| 3 | 50mm PLC Extruder line | Cabletec | 1 |

| 4 | 70mm PLC Extruder line | Cabletec | 1 |

| 5 | 90mm PLC Extruder line | Cabletec | 1 |

| 6 | 16A High speed braiding machine | Cabletec | 18 |

| 7 | 2A Type doubling winding machine | Cabletec | 5 |

| 8 | Medium cross-section coiling machine | Cabletec | 1 |

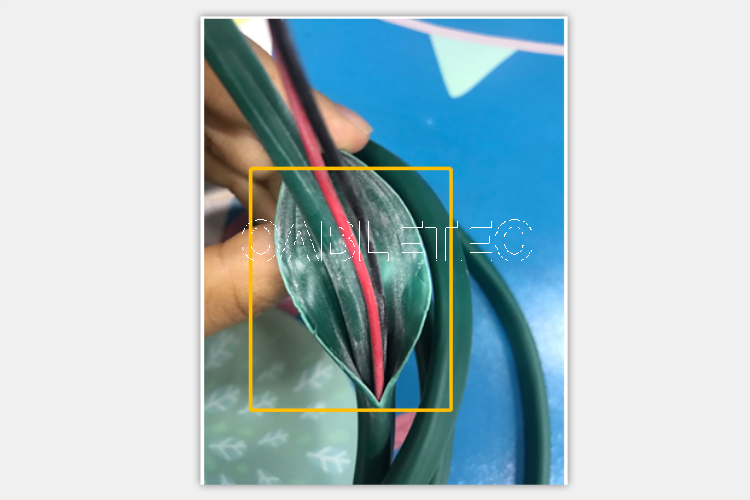

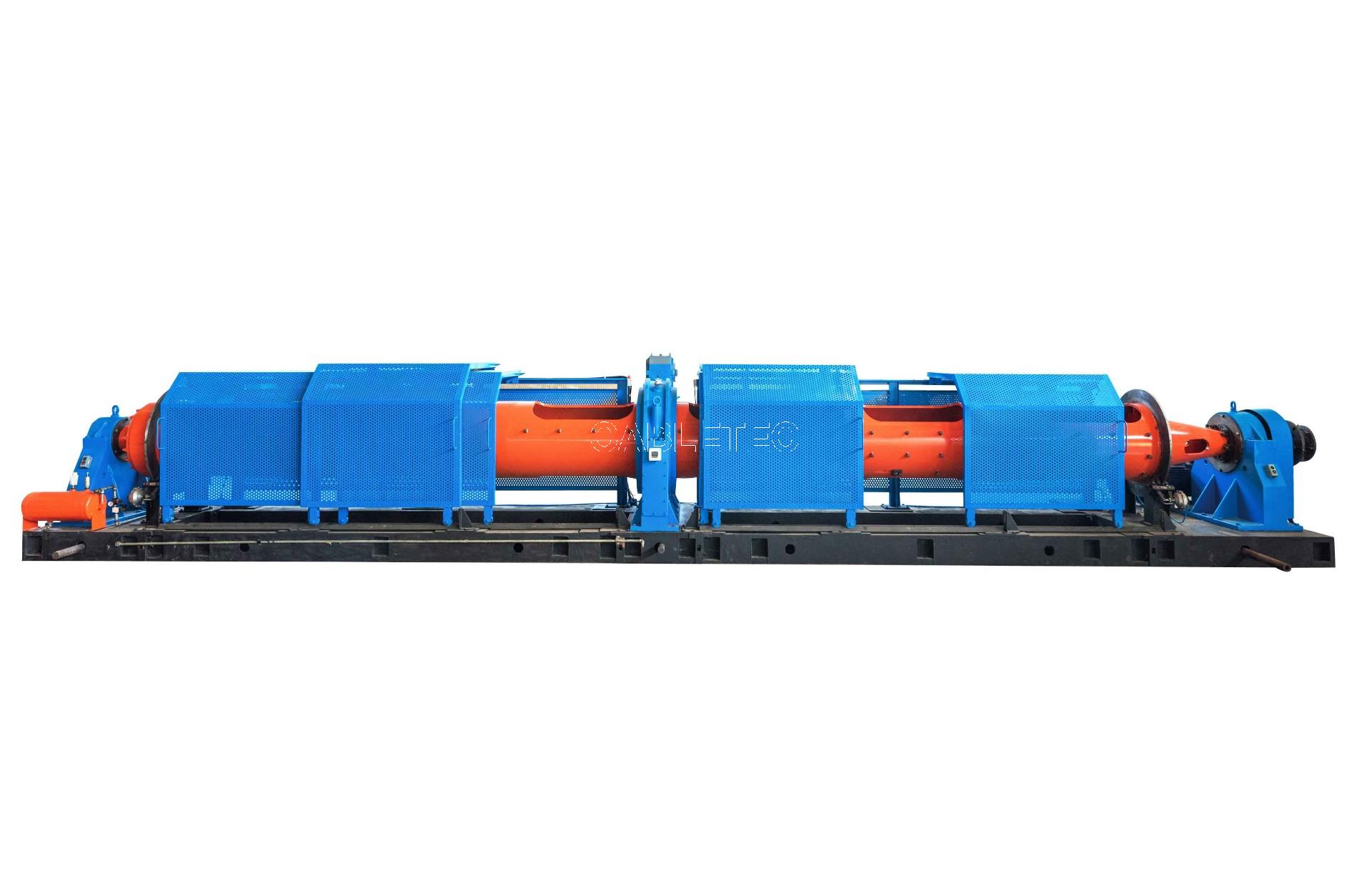

1. 400mm Bunching machine

1.1 Twisted copper wire diameter: 0.05 ~ 0.28mm

1.2 Twisted copper wire section: 1.2 mm²

1.3 Pitch: 4.05 ~ 69.12mm

1.4 Power supply: 380V 50Hz

1.5 The height of the Installation place: less than 1000 m

2. 500mm Bunching machine

2.1 Wire cross section(mm2): 2

2.2 Copper wire diameter(mm): 0.08 ~ 0.32

2.3 Pitch(mm): 5.34 ~ 40.02

2.4 Power supply: 380V 50Hz

2.5 The height of the Installation place: less than 1000 m

3. 50mm PLC Extruder line

3.1 Application of the core conductor diameter: Φ0.25mm-Φ4.5mm

3.2 Complete external diameter: Φ0.6mm-Φ5.0mm

3.3 Extrusion volume: 70KG/HR (crosshead open, soft PVC)

3.4 Machine center height:1000mm

4. 70mm PLC Extruder line

4.1 Application of conductor diameter: Φ1.0mm-Φ8.0mm

4.2 Complete external diameter: Φ1.5mm-Φ12.0mm

4.3 Extrusion volume: 150KG/HR (Crosshead open, soft PVC material)

4.4 Machine center height: 1000mm

5. 90mm PLC Extruder line

5.1 Application of conductor diameter: Φ3.0mm-Φ20.0mm

5.2 Complete external diameter: Φ5.0mm-Φ25.0mm

5.3 Extrusion volume: 300KG/HR (crosshead open, soft PVC material)

5.4 Extrude line speed: Max 200M/Min (Depending on completion of the external diameter sure)

5.5 Machine center height:1000mm

6. 16A High speed braiding machine

6.1 Braiding diameter range: Maximum ф14mm, generally ф0.5 ~ ф9mm, if more than ф9mm recommended 24A high-speed weaving machine, such as with 16A high-speed weaving machine, cable quality may not meet the national or industry standards. (Standard ф5, ф7.8, ф9 a total of 3 sets of upper and lower mold)

6.2 Range of braiding pitch: 3.2~63.5mm

6.3 Range of braiding silk: 4×ф0.08~9×ф0.20

6.4 Material of braiding silk: Aluminum-magnesium alloy wire, glass wire, copper wire, stainless steel wire, polyester yarn

7. 2A Type doubling winding machine

7.1 Wire diameter: 0.08~0.20mm

7.2 Wire Winding quantity: 1-9

7.3 Head quantity: 2pc

7.4 Pay off bobbin size: MAX 250(standard:18 heads tension pay off)

8. Middle cross-section coiling machine

8.1 Wire diameter: 10mm2~70mm2(Hard structure),10mm2~95mm2(Soft structure)

8.2 Rotation speed of principle machine: 0-200 rpm

8.3 Outside diameter of cable bundle:≤Φ650mm

8.4 Number of cable bundle slots: 3 slots

8.5 Power of motor: 5HP Variable frequency control

8.6 Inside diameter of cable bundle: Φ200mm (based on the client requirements)