- Product Details

- Video Center

1. Usage

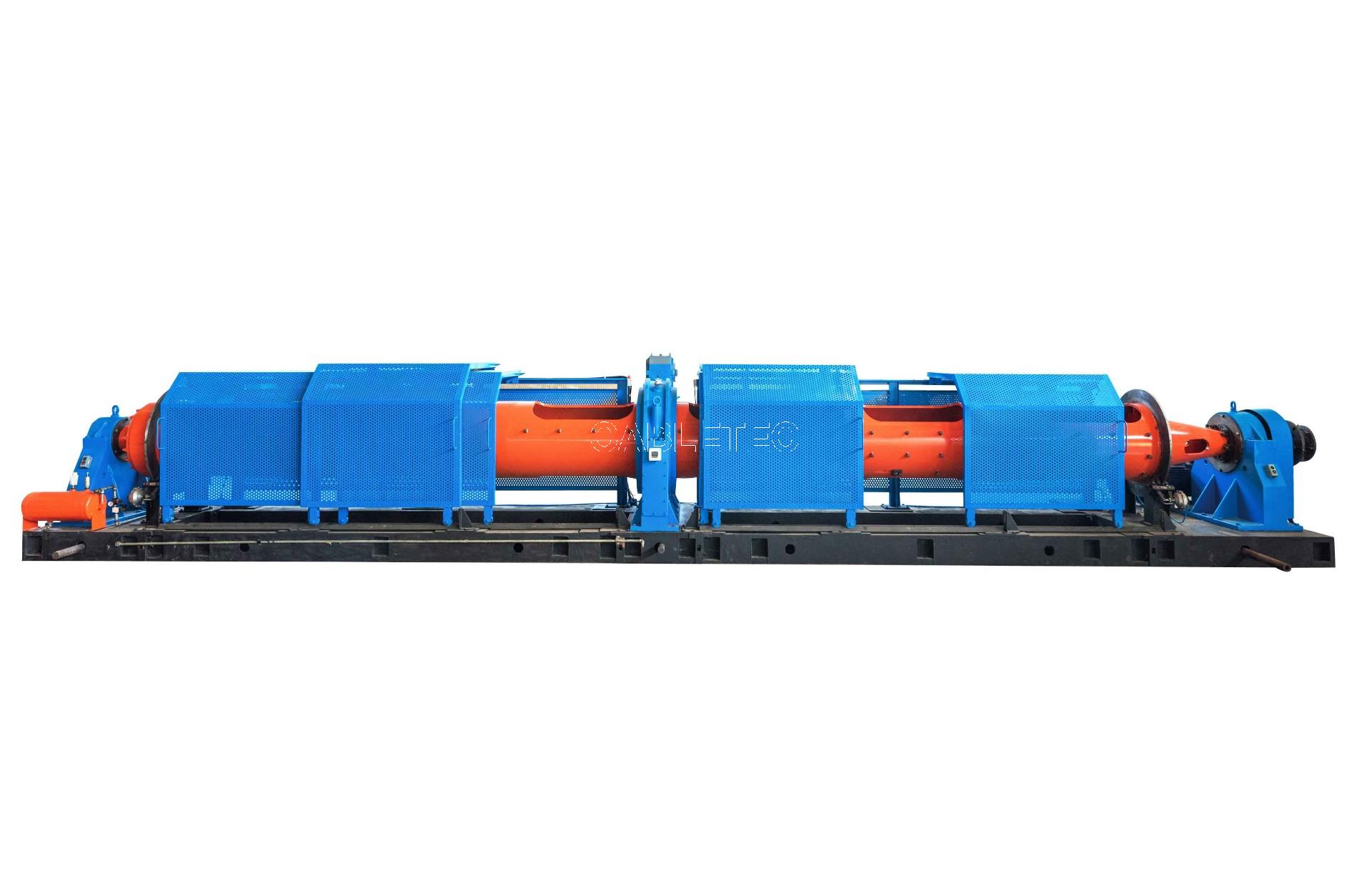

Galvanic wire tinning line is a brand-new and high-quality equipment which is mainly used for plating Tin on the bare copper conductor production. It mainly includes mechanical, electrical, other auxiliary system and environment protection equipment such as waste air scrubber and vacuum evaporator, spare parts, related tools, and software etc. delivered with equipment.

2. Compose

1 | Straightening system | 1set |

2 | Electrolytic cathodic degreasing | 1set |

3 | Five stage step flushing | 1set |

4 | Tension device 1 | 1set |

5 | Pickling tank | 1set |

6 | Pre-tinned tank | 1set |

7 | Tension device 2 | 1set |

8 | Plating tank | 1set |

9 | Five stage step flushing | 1set |

10 | Wire drying device | 1set |

11 | Cone flyer pay off | 1set |

12 | Tension rack+Barrel type take up | 1set |

13 | Copper bar and cable for connecting electric cabinet to device | Provided by customer |

3. Main parameters

3.1. Designed line speed: 15m/s

3.2. Inlet wire material: Copper wire

3.3. Suitable diameter: 1.2-2.6mm Soft wire

3.4. Requiremnt to the copper wire: Low oil pollution and non-oxidation, soft

3.5. Suitable material: Tin

3.6. Thickness of tin: 1 to 10 µm

3.7. Total installation power: 175kw

3.8. Voltage: 3x380/50 Hz

3.9. Control voltage: 24V DC, 230V AC

3.10. Max. Temp. for environment: 45°-50°C

3.11. Noise: Max. 85 dB (A)

3.12. Plating current: 2x5000 A, 8 V

3.13. Degreasing current: 500 A, 12 V

3.14. Electroplating immersion length: 2x15 m

3.15. Plating immersion length: About 60m