Structure principle and operation procedure of aluminum extrusion machine

Feb 25, 2022|

Feb 25, 2022| View:478

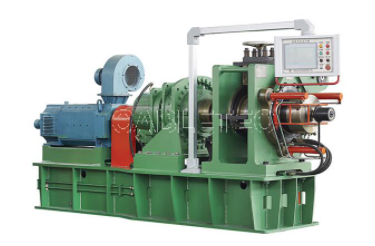

View:478I. Aluminum extrusion machine host

It can be divided into the following parts.

1. Transmission, extrusion system.

It relies on the main frequency converter to control the frequency-controlled motor, which is passed to the screw step by step through the reducer box distribution box and cross spline to complete, in which the program entered in the frequency converter and the parameter values have been set at the factory to complete the equipment, and cannot be changed at will.

2. Heating and cooling system.

Is composed of barrel heating and cooling, die heating, screw core heating and cooling, controlled by the electric cavity program, but also manually according to their own experience, another manual forced cooling function to control the instantaneous temperature increase.

3. Automatic material supply system.

It is controlled by time relay or level meter to transmit signal, when there is a shortage of material, the level meter transmits signal, the system starts to feed, after feeding full level meter signal interrupts, the feeding stops.

4. Feeding system.

It is controlled by frequency converter. When adding less material, the current and torque of main machine will be lowered. On the contrary, it increases. When feeding too much material, the actual current exceeds its rated current or torque exceeds its set value, the main machine will overload and alarm stop, generally controlled at 50%~80% of the rated value.

5. Vacuum exhaust system.

The vacuum pump is directly controlled by a button, and the solenoid valve opens when the vacuum opens and closes when the solenoid valve closes.

Second, aluminum extrusion machine operating procedures.

1. Check whether the oil pressure system is leaking and whether the air pressure is normal.

2. Check whether the conveyor belt, cold bed and material storage table are broken and scuffed.

3. Confirm the length of the aluminum profile before stretching, then predetermine the stretching rate and determine the stretching length, i.e. the position of the main chuck movement, usually the stretching rate of 6063T5 is 0.5% - 1%, and the stretching rate of 6061 T6 is 0.8% - 1.5%.

4. Confirm the clamping method according to the shape of the aluminum profile, large section hollow profile, can be stuffed with stretching pad, but try to ensure sufficient clamping area.

5. When the aluminum profile is cooled to below 50℃, the profile can be stretched.

6. When the profile is bent and twisted at the same time, the twist should be corrected first and then the bend should be pulled.

7. The first and second one will be test-drawn to confirm whether the predetermined stretching rate and clamping method are suitable. Visually bend, twist and twist, check the plane gap, flare and parallel mouth of the profile, and if they are not suitable, adjust the stretching rate appropriately.

8. If the normal stretching rate still cannot eliminate the bending and twisting, or cannot make the geometric dimension qualified, the operator should be notified to stop extrusion.

9. The profiles on the cooling table should not rub against each other, collide with each other, overlap and stack, and prevent rubbing.

The efficiency and service life of the aluminum extrusion machine have a great relationship with the installation order of the extrusion machine. In addition to the weight of the equipment itself and the weight of the raw materials used for production, the equipment foundation of the general aluminum extrusion machine should also bear the dynamic load when the extrusion machine is working.

Attention.

After the installation of the extruder, process technicians should carefully read the equipment manual, according to the requirements in the manual, the development of test production of plastic products process, test operation procedures, material plans and test tools and test run time. Understand and be familiar with the structure of the equipment and the function of each part, and be familiar with the function and usage of each button and switch.